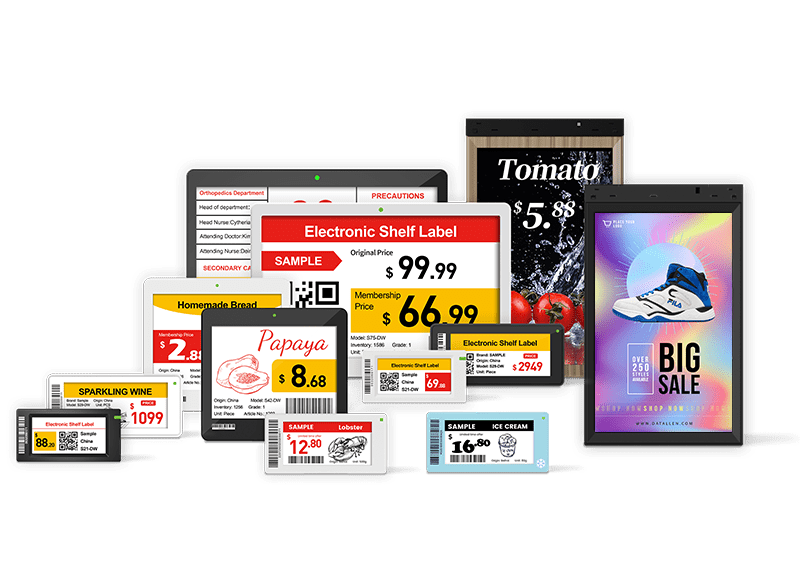

In the competitive world of warehousing, where efficiency and precision are paramount, digital shelf tags are emerging as crucial solutions to many operational challenges.

Beyond simply displaying prices, these innovative labels enable real-time data updates, streamline inventory management, and optimize the physical layout of the warehouse.

For businesses aiming to stay ahead, investing in electronic price tags can significantly enhance their warehousing operations, delivering tangible benefits from improved inventory accuracy to better space utilization.

Key Considerations for Warehouse Layout Construction

When designing a warehouse layout, several factors must be considered to ensure optimal efficiency and functionality:

1. Space Utilization: Maximize the use of vertical and horizontal space to store more inventory.

2. Accessibility: Ensure that all storage areas are easily accessible to workers and equipment.

3. Flow of Goods: Design the layout to facilitate smooth and efficient movement of goods from receiving to shipping.

4. Safety: Incorporate safety measures to protect workers and prevent accidents.

5. Technology Integration: Plan for the integration of technology, such as esls, to streamline operations.

Warehouse layout design is one of the foundational elements of operational efficiency. However, many warehouses face challenges with optimizing space and minimizing inefficiencies, especially when inventory is constantly changing. Traditional fixed shelving and manual labeling often lead to bottlenecks, errors, and slower workflows.

In contrast, a flexible and adaptive layout—augmented by digital shelf tags—can drastically improve organization and workflow.

Benefits of Implementing Electronic Price Tags in Warehouses

Electronic Price Tags offer numerous benefits that can significantly enhance warehouse operations, leading to improved efficiency, accuracy, and overall performance. Here are the key advantages and improvements you can expect:

Enhanced Inventory Accuracy:

1. Real-Time Updates: Digital Shelf Tags sync with the warehouse management system (WMS) in real-time, ensuring that inventory data is always up-to-date. This reduces the risk of discrepancies and inaccuracies that often arise from manual inventory management.

2. Automated Reconciliation: Automated updates eliminate the need for manual price changes and stock checks, reducing the likelihood of human error and ensuring that inventory records are consistently accurate.

Enhanced Worker Productivity:

1. Streamlined Tasks: Electronic price tags streamline inventory management tasks, allowing workers to focus on more productive activities. This can significantly reduce the time and labor required for routine inventory management.

2. Faster Order Picking: With real-time updates and clear visual indicators, workers can quickly and accurately locate items, reducing search times and increasing picking efficiency. This leads to faster order fulfillment and improved customer satisfaction.

3. Reduced Downtime: With automated updates and real-time data, workers can focus on their tasks without interruptions, leading to reduced downtime and increased throughput.

Cost Savings:

1. Long-Term Savings: Over time, ESLs can reduce labor costs and minimize the need for paper labels, leading to significant cost savings. The initial investment is offset by the long-term benefits of improved efficiency and reduced errors.

Improved Inventory Management:

1. Dynamic Slotting:

Electronic labels facilitate dynamic slotting, allowing you to adjust your warehouse layout based on real-time data. This optimizes the use of storage space and reduces material handling costs.

2. Better Visibility: Enhanced visibility into inventory levels and operational data enables better decision-making and strategic planning. This helps in identifying and addressing stockouts or overstock situations proactively.

Enhanced Customer Satisfaction:

1. Accurate Information: Customers receive accurate and up-to-date information about product availability and pricing, leading to a more pleasant shopping experience and higher satisfaction.

2. Timely Fulfillment: Faster and more accurate order picking and packing processes ensure that orders are fulfilled promptly, enhancing customer loyalty and repeat business.

Material Handling Optimization:

1. Optimized Storage: Efficient slotting and dynamic inventory management optimize the use of storage space, reducing material handling costs and improving overall warehouse organization.

2. Reduced Waste: Accurate inventory data helps minimize waste by ensuring that stock levels are managed effectively, reducing the risk of overstocking or stockouts.

Data-Driven Decision Making:

1. Informed Decisions: Real-time data and enhanced visibility provide valuable insights, enabling better decision-making and strategic planning. This helps in optimizing inventory levels, reducing costs, and improving overall warehouse performance.

By implementing electronic shelf labels, warehouses can achieve significant improvements in various aspects of their operations, from inventory accuracy and worker efficiency to cost savings and customer satisfaction. Datallen's comprehensive solutions and support ensure that you can leverage the full potential of electronic labels to transform your warehouse management practices.

How to Choose the Right Digital Shelf Tags for Your Warehouse

Selecting the appropriate digital shelf tags involves considering several factors:

1. Connectivity: Wireless communication via protocols like 2.4GHz, Bluetooth, or Wi-Fi, ensures that updates are transmitted quickly and accurately across the system.

2. Integration: Select tags that can seamlessly integrate with your existing WMS and other systems.

3. Durability: Ensure the tags are robust enough to withstand the warehouse environment, including temperature variations and physical handling.

4. Battery Life: In environments where hundreds or even thousands of labels need to be deployed, choosing e ink shelf labels with long-lasting batteries is essential. This reduces maintenance efforts and ensures that labels remain functional without constant replacements.

5. Scalability: Choose a solution that can grow with your business, supporting future expansions and additional features.

6. Display Type and Size: For larger warehouses or stores with high shelving, it's critical to select e ink shelf labels with large, clear displays that can be easily read from a distance. In addition, E-ink technology offers a high level of contrast, making the text visible even under varied lighting conditions.

Key Considerations for Implementing Digital Shelf Tags

When implementing digital shelf tags, several key considerations can ensure a smooth and successful transition. These considerations not only address the practical aspects of installation and usage but also highlight the comprehensive support and tailored solutions offered by Datallen. Here are some essential points to keep in mind:

Training:

1. Ease of Use: Training is simplified with Datallen's user-friendly operation guides and instructional videos. Our intuitive interface ensures that warehouse staff can quickly and confidently operate digital price labels.

2. Technical Support: Datallen provides on-site or remote training sessions to ensure that your team is fully prepared and knowledgeable about the system.

Testing:

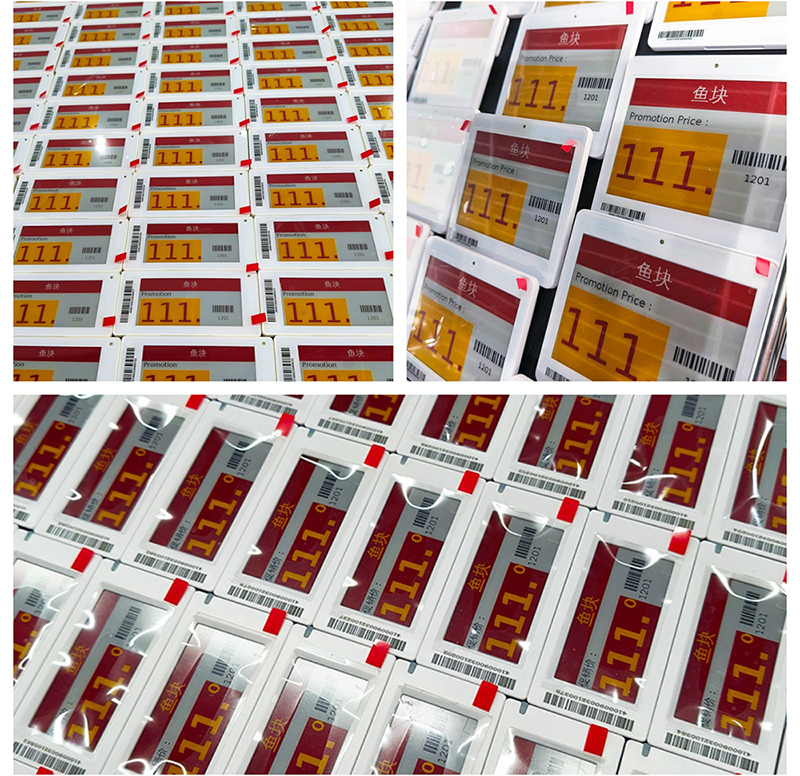

1. Sample Testing: Before committing to a full-scale deployment, Datallen offers sample tags for thorough testing. This allows you to identify and resolve any potential issues, ensuring that the system meets your specific needs.

2. Pilot Programs: Implementing a pilot program in a small section of your warehouse can provide valuable insights and help fine-tune the system before a broader rollout.

Warehouse Layout and Size:

1. Custom Solutions: Consider the size of your warehouse and the volume of goods stored. Datallen offers a range of digital price labels in various sizes to accommodate different product dimensions and storage requirements.

2. Comprehensive Assessment: Datallen provides a detailed assessment service to evaluate your warehouse layout and recommend the optimal number and placement of e ink papers. This ensures that every item is easily locatable and manageable.

Connectivity and Infrastructure:

1. Reliable Connectivity: Choose tags that support robust wireless communication technologies such as Bluetooth, Wi-Fi, or 2.4GHz. Datallen's tags are designed to maintain stable connections even in challenging warehouse environments.

2. Network Integration: Ensure that the e ink paper can seamlessly integrate with your existing warehouse management system (WMS) and other infrastructure. Datallen's solutions are compatible with a wide range of systems and can be customized to fit your specific needs.

Rugged Design and Durability:

Digital shelf tags must withstand the rigors of a warehouse environment, including temperature variations and physical handling. Datallen's tags are built to last, with durable materials and long battery life.

Scalability and Flexibility:

1. Future-Proof Solutions: Choose a solution that can grow with your business. Datallen's digital shelf tags are scalable, allowing you to add more tags and features as your operations expand.

2. Versatile Applications: Beyond inventory management, digital shelf tags can be used for various purposes, such as tracking asset locations, managing work orders, and enhancing overall warehouse visibility. Datallen's flexible solutions can be adapted to meet a wide range of needs.

Security and Data Protection:

1. Data Security: Protect sensitive data by implementing robust security measures. Datallen's digital shelf tags use encrypted communication to ensure that your data is secure and confidential.

2. Compliance: Ensure that your digital shelf tag system complies with industry standards and regulations. Datallen adheres to the highest standards of data protection and can help you meet compliance requirements.

By considering these key factors and leveraging Datallen's comprehensive support and tailored solutions, you can successfully implement digital price labels and transform your warehouse operations. Our goal is to provide you with the tools and expertise needed to achieve greater efficiency, accuracy, and productivity in your warehouse.

Conclusion

Digital shelf tags offer a cost-effective and efficient solution to optimize warehouse operations. By improving inventory accuracy, reducing human error, and enhancing worker efficiency, electronic labels can help warehouses stay competitive in today's fast-paced market. With the right technology and strategic approach, e ink price tags can revolutionize the way warehouses are managed, leading to greater efficiency, productivity, and a competitive edge in the marketplace.

For more insights, check out:

1. Smart Warehousing Case Study

2. Smart Warehouse Solutions for Chinese Factories

3. Smart Factory Solution for Manufacturer

4. Advantages of 2.4G Private Protocol in Electronic Shelf Labels