In the vast landscape of modern logistics, warehouses stand as the backbone of supply chains. For a leading Chinese factory warehouse, covering thousands of square meters and housing a diverse array of raw materials, semi-finished, and finished goods, the challenge was clear: how to streamline operations while maintaining accuracy and responsiveness. The traditional approach of manually updating labels was proving inefficient, error-prone, and increasingly unsustainable.

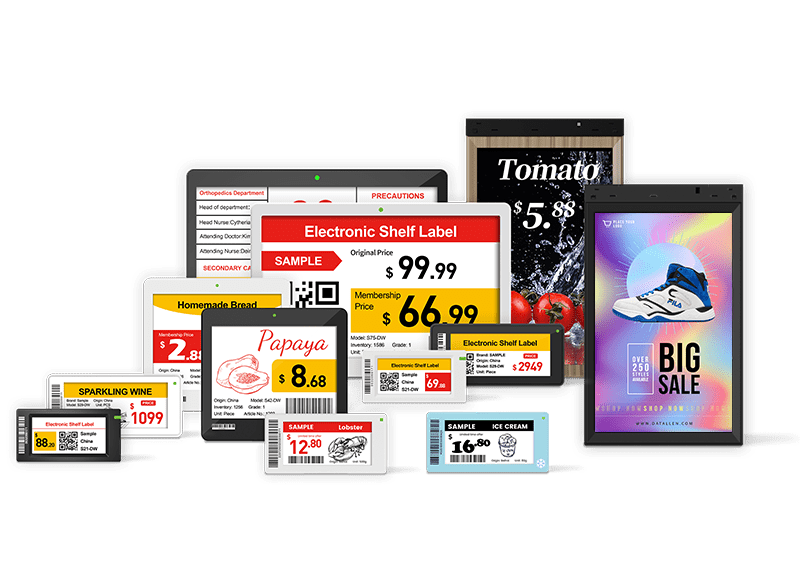

After a thorough evaluation of cost, technology, and service, the warehouse management team opted for Datallen’s electronic label solution. This decision marked the beginning of a transformative journey towards smarter, more efficient warehouse operations.

Enhanced Efficiency and Accuracy

"The transition to Datallen’s electronic label system has been nothing short of revolutionary," remarked the warehouse manager. The implementation of electronic shelf labels has significantly reduced the time and effort required for routine tasks such as price updates and information changes. By automating these processes, the system minimizes human errors and ensures that all product data is accurate and up-to-date.

Seamless Integration with WMS

One of the key advantages of Datallen’s solution is its seamless integration with the existing Warehouse Management System (WMS). This integration enhances the functionality of critical operations like material tracking, inventory monitoring, and sales analysis. With real-time data at their fingertips, warehouse managers can make informed decisions, optimize inventory levels, and improve overall supply chain efficiency.

Economic Benefits

While the initial investment in electronic shelf labels is higher compared to traditional paper labels, the long-term benefits are substantial. The increased operational efficiency, reduced error rates, and enhanced sustainability make the investment well worth it. "From an economic standpoint, the return on investment is evident," the warehouse manager noted. "We have seen a significant reduction in operational costs and a marked improvement in our ability to respond to market changes."

Conclusion

For the Chinese factory warehouse, the adoption of Datallen’s Smart Warehouse Solutions has been a game-changer. The electronic label system has not only streamlined operations but also elevated the warehouse’s performance to new heights. As the logistics industry continues to evolve, the integration of advanced technologies like electronic shelf labels will be crucial for staying competitive and meeting the demands of a fast-paced market.

By embracing innovation, this warehouse has set a benchmark for others in the industry, demonstrating that the right technology can drive significant improvements in efficiency, accuracy, and profitability.